INFRARED MOISTURE SURVEYS

INFRARED MOISTURE SURVEYS

For the majority of roofing systems, Infrared Moisture Surveys are the most effective way to locate and document water intrusion. Infrared Roof Surveys help avoid unnecessary repairs and premature roof replacements. This can add up to hundreds of thousands of dollars in savings.

Use Infrared Roof Moisture Surveys To:

- Locate damaged roof areas and quickly repair them.

- Determine acceptable roof areas that can be kept.

- Provide a quality assurance report after new installations.

- Verify roof condition before a warranty expiration or building purchase.

- Determine the extent of storm damage for an insurance claim.

- Provide legal documentation on the condition of the roof.

- Dispute resolution.

- New building enclosure commissioning.

- Real estate transactions.

- Building maintenance.

The Hidden Costs Of Water Damage

Moisture damage in the roof decreases the effectiveness of the building's insulation. This causes the life span of the insulation to be reduced and creates increased heating costs. It also creates mold growth which can spread to other parts of the building, cause environmental hazards, as well as further reducing the lifespan of other building materials.

Hiring Pros is Essential.

Accurate infrared roof moisture detection requires extensive experience and equipment matched to this task.We're your source for accurate tests you can count on.

How It Works:

- During the day, the roof absorbs sunlight and heats up. Due to greater thermal capacity, any areas of the roof containing moisture will absorb more heat during this time than areas with dry insulation. At night, the roof releases this solar gain, and the dry areas of the roof will cool down faster than those areas retaining moisture.

- Utilizing our professional imaging equipment after sunset, we can locate areas with moisture damage based on their thermal signature. We plainly mark these areas on the visible roof surface with spray paint or crayon for fast and easy repairs.

- We record all relevant details of each problem found and supply a comprehensive report to assist our clients with future repairs or legal documentation.

- All Testing Solutions uses only certified Thermographers and state-of-the-art equipment to provide professional surveys in compliance with industry standards.

survey contact us at 800-910-4341.

INFRARED ELECTRICAL INSPECTIONS

INFRARED ELECTRICAL INSPECTIONS

What Does It Inspect and How Does It Work?

An Infrared Electrical Inspection can be used to scan any electrical component, including wiring, connections, breakers, fuses, circuits, switches, disconnects, and more.

Malfunctioning or overloaded electrical equipment will give off more heat than normal due to increased electrical resistance. This heat can be detected and documented with the use of certified infrared imagers. Detecting electrical hot spots allows for repair or replacement of the affected equipment before failure occurs.

When you're running a business, having reliable equipment is essential for maximizing efficiency and keeping downtime and profit loss to a minimum. Routine maintenance and reactive fixes are helpful, but knowing when your equipment is going to break down and proactively fixing it can save you time and money. Below, we'll explain what an infrared electrical inspection is and the benefits of conducting one in your facility.

Risk Of Not Getting An Infrared Electrical Inspection

Neglecting to get your equipment inspected with IR can let faulty components to continue to break down and fail prematurely. Infrared electrical inspections are crucial for maintaining your company's uptime and minimizing costly repairs and outages. For more information on IR inspections, or to schedule one for your business, contact one of our highly trained professionals today.What Is An Infrared Electrical Inspection?

An infrared (IR) electrical equipment inspection is an examination of any electrical components or machinery utilizing IR technology to detect inefficient operation or equipment failure.

Below are the five most significant benefits of an IR electrical inspection:

- Identifies Problems Early

Excessive heat in your equipment is a clear sign that something isn't functioning correctly. IR scans can predict when and where equipment failure will occur, allowing you to repair accordingly. - Reduces Downtime

IR scans work while your equipment is running, which means you won't need to shut down your business for an inspection. - Keeps Testers Safe

These scans use infrared imagers to find inefficiencies, which means the technician and your employees remain completely safe throughout the process. - Improves the Effectiveness of Routine Maintenance

Routine maintenance is important, but problems detected by IR aren't always visible. An infrared inspection can help pinpoint the areas that would otherwise be missed during routine maintenance. - Helps Prevent System Failure

Regular IR inspections will help ensure your equipment remains up and running, so your business can maintain efficiency and avoid being caught off guard.

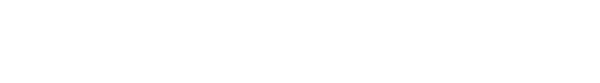

Ultrasonic/infrared steam trap testing

Steam energy, whether produced on-site or purchased for a power utility, typically accounts for one of the main expenditures of any commercial or industrial facility. The incorrect functioning of even a small percentage of steam traps can result in significantly higher energy costs. Malfunctioning steam traps can also cause severe operational problems as well as dangerous corrosion damage to nearby pipping and related valves. Annual steam trap testing is the best way to ensure limited operational costs and maximize the efficiency and longevity of any steam system.

Why should you have your steam traps tested?

A steam system that has not been maintained for a period of time will have many failed traps. Experts estimate that facility with no active steam trap testing program in place will have 50% of its traps blowing steam. These failed steam traps not only spike wasted energy costs, but also minimize the efficiency of your heating system. Implementing a regular testing program will solved these problems.

What are failed steam traps costing you?

With energy prices on the rise, now it's more important than ever to have cost saving steam trap program in place. To understand the cost of steam trap failure consider this: An unchecked blowing steam trap at 150 pounds per square inch with an orifice diameter if 3/16 inches will waste 120 pounds of steam. Using an average cost of steam at $12.00 per 1000 pounds produced, one blowing trap will expend approximately #38.50 per day, or an amazing $14,050 a year. The first step in determining how much your facility might be wasting is to conduct a steam trap survey. Most of our clients see a full return on testing and repair costs in only 2 months!

How often should I have my steam traps checked?

An annual testing program is recommended to ensure a maximum return on your investment. This included a full diagnostic report on all steam traps surveyed from year to year.

What does my All Testing Solutions steam trap service include?

- All surveyed traps are tagged with permanent brass tags for the purpose of easy identification as well as tracking and trending

- Inspection for faulty check valves and steam leaks in addition to trap testing

- All failed traps tagged and photographed to be put in an itemized report

What does my All Testing Solutions steam trap report include?

- Complete master trap listing of all steam traps testing including trap typer, manufacturer, model, application, pipe size, orifice size, and location of trap

- A dollar loss cost analysis based on-line pressure, degree of failure, and specific client cost to product 1000 pounds of steam

- An individual trap performance section to associate dollar loss to failed traps

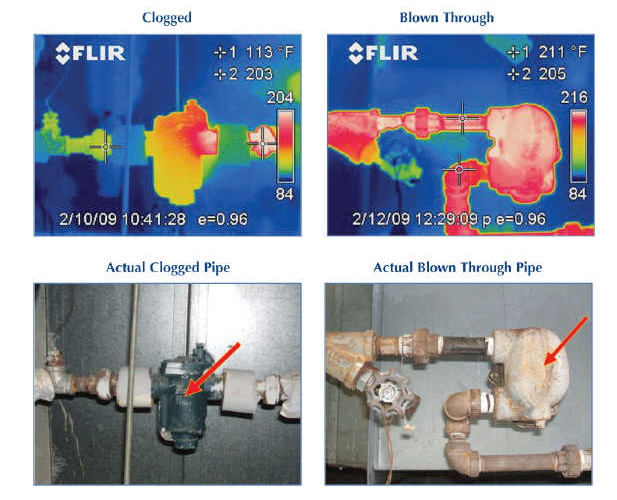

Heat loss inspection

Due to the ever-increasing cost of energy, conservation and efficiency have become priorities:

All Testing Solutions offers building envelope testing. Inspecting your building's envelope using infrared thermography will identify porous areas in the facility where you can see your money, in the form of heat, seeping out of faulty windows, doors, facades, etc.

A building envelope test will pinpoint areas where gross heat loss is occurring, identify the probable cause, and work with your facility's personnel to best determine how repairs should be made.

By sealing your building, your heating and cooling equipment will not have to work as hard to maintain a constant temperature, saving your building on future equipment replacement and repairs.

Testing your building's envelope will not only reduce energy costs and drafty conditions in your facility but it will also increase the operation lifetime of your heating and cooling equipment.

Heat loss - commercial

Heat loss scanning of building envelopes is an invaluable tool for locating areas of heat/energy loss. Building envelope scanning must be performed late at night after the solar radiation has been released from the building surface. A minimum of a 20 degree temperature differential between the interior an exterior of building is needed to ensure the proper results.

Our experienced technicians are able to determine if the thermal profiles found are of normal profile or problems that need correction. With rising energy costs, building envelope scanning is a must have in any company's energy conservation program.

Cold air infiltration can also be evaluated by scanning the exterior walls from the interior of the building with access permitting.

Mechanical systems

Motors:

motors are scanned to determine if the surface temperature exceeds the nameplate rating. If a motor is dirty, overloaded, and undersized or near end of life thermal imaging will detect uneven heating patterns indicating problems

Shafts:

shafts that show abnormal heating patterns will indicate misalignment

Bearings:

elevated temperature on bearings will indicate improper greasing or worn components

Underground pipes:

Thermal imaging is extremely effective in identifying the location of pipes for mapping purposes and for locating broken or leaking hot water and steam pipes. Boiler systems with leaks in return piping that are constantly requiring fresh water to make up volume are operating extremely inefficiently. Underground testing of exterior piping is also performed late in the evening after solar radiation has been released from the ground.

Electrical Systems

Infrared thermography is an ideal inspection technique for scanning electrical equipment for defective components. Normal wear, chemical contamination, corrosion, fatigue and faulty assembly or installation, any of the above may lower the conductivity and raise the resistance level of the component in question. Such a rise in component resistance will increase the amount of power dissipated in the form of heat. This in turn will cause an increase in the temperature of the component.

This excessive heat, evidenced by the increased surface temperature of the component, can be readily noted and the temperature rise measured by the infrared system. The increased temperature indicated a potential trouble spot and possible future failure of the competent.

The infrared inspection is carried over while the electrical system is under load and there is no physical contact with the system, thus making it an excellent preventative maintenance tool, which causes no disruption to the normal operating routine of a facility.

At the plant/building level al the major electrical equipment such as the sub-station motor control centers, switchgear, circuit breaker panels, electric motors, etc. Can be readily checked for component problems, which are at an excessive temperature, this indicating potential problems.

In power generating, transmission and distribution systems electrical energy is transferred from one facility through a series of mechanical interfaces associated with connectors, insulators, switches, bushings, and buses, etc. Each resultant temperature increase, again pointing to a potential problem.

Routine infrared scanning of electrical components is thus a valuable preventative maintenance tool whereby early corrective action may be taken preventing costly breakdowns and/or plant hazards.